Kathryn's UNH Day in the Life

Are you wondering what a day in the life of a UNH student looks like? Welcome back to our Day in the Life of a UNH Wildcat series, where we put the spotlight on students from different academic majors and class years to see what their day in the life looks like.

Meet Kathryn Carlson ‘24, a chemical engineering major at UNH and a Process Validation intern at Lonza in Portsmouth this summer. From learning about the Process Validation field, to being responsible for document review, to participating in a mixing study, follow along on Kathryn's day.

Meet Kathryn Carlson ‘24

Hometown: New Boston, NH

Major: Chemical Engineering

Kathryn Carlson

What is Lonza?

Lonza is an international company based out of Switzerland with over 30 sites globally. The most popular site for UNH students to intern and eventually work at is located in Portsmouth, NH (just a 15-minute commute from campus). learn more about lonza

What am I doing at Lonza?

Lonza produces Active Pharmaceutical Ingredients (API), which are the active proteins used in pharmaceutical drugs. Pharmaceutical companies, or "customers," will come to Lonza and work with us to create the API, most of which are for life-saving and life-changing drugs (such as the Moderna vaccine).

I work with a team called Process Validation (PV) that works under the Manufacturing Science and Technology (MSAT) department. Process Validation works with the engineering teams, quality teams and the customer to make sure the whole process of creating an API is up to the standard of the customer, as well as the standard of the FDA.

Morning

7:30 a.m. Work day starts

I sit in the Manufacturing Science and Technology (MSAT) seating area at the 101 International Drive office of the Lonza Portsmouth site. I typically start my day by checking my emails and Microsoft Teams messages. Then, I work on a simple task to get the day started. Today, I work on scanning Batch Records. Batch Records contain any data collected from the manufacturing area, where the Active Pharmaceutical Ingredients (APIs) are actually made and studies for Process Validation (PV) are run. It is necessary to scan and upload them to the online network, so I can then take data to reference in reports.

9 a.m. Daily Huddle meeting

The "Daily Huddle" is a meeting every morning at 9 where the whole PV team meets on Microsoft Teams and checks in on items such as safety incidents, recognition when people do a good job on a project, and issues that need to be brought to upper management. After the approximately 20-minute meeting, I resume any tasks I was working on the day before, such as:

- Emailing other departments to review documents such as protocols and reports

- Responding to comments on a protocol uploaded to the network

- Mining data from the Batch Records and recording them in "Summary Reports"

10 a.m. 1:1 meeting with manager

Every week, I have a 1:1 meeting with my manager to check in on my projects and tasks I have been assigned. I also ask questions and we have good conversation about a variety of topics: the company and how it works, what positions have what responsibilities and professional development topics. I am lucky that my manager is easy to talk to because the more I learn about the professional field, the more I can determine what I want to do after graduation.

10:30 a.m. Tasks

After morning meetings, I will continue working on my project. This can be the data mining for reports or editing other documents. Most of my work is document editing and cross-referencing information with Process Descriptions or Protocols to make sure any data reported is correct.

11 a.m. JPT meeting

Joint Project Team (JPT) meetings are when every department responsible for the API addresses issues or concerns that need customer input. There is a Project Manager (PM) who is in charge of seeing the API through to the end and the main communicator between Lonza and the customer. The PM holds accountability to each department responsible and leads the meeting by facilitating questions from both the customer's side as well as our side. These meetings happen every other week throughout the whole process and I learn a lot about the business side of the industry by sitting in on the meetings.

Afternoon

12 p.m. Lunch

Some days I bring in lunch and eat at my desk, and other days I buy lunch from the Lonza café downstairs and eat in the cafeteria with the other interns.

12:30 p.m. Tasks

After lunch, I will continue working on whatever document I am currently editing. For the documents I’m responsible for during my internship, I am in charge of making sure the documents get reviewed by other departments before they become “effective” on the network. This consists of emailing other Lonza employees to make sure they review the document. Once a document is “internally reviewed” by each respective department, it gets sent to the customer via email for a final review. I have worked on the process of a document from start to finish (draft to “effective” on the network) and have learned that it takes a lot of work and collaboration to create an official document.

Kathryn's desk at Lonza

1 p.m. Mixing study

Mixing studies are one of the many studies that PV performs to validate equipment. This mixing study takes place in a 6,500 L tank. The goal is to test how long it efficiently takes the tank to mix 6,500 L of material because if the tank is the same efficiency at its maximum capacity (6,500 L) compared to a much lower capacity (1,000 L), then any amount bracketed between those studies (ex. 4,000 L) is validated.

In order to go back into the manufacturing area, you need to "gown up." This involves changing into scrubs in a locker room, removing all jewelry and makeup, covering hair with hair nets and wearing disposable booties over shoes to ensure no contamination of the manufacturing area. There are “suites” within the manufacturing area that involve another layer of coverage before entering, so you put on a jumpsuit and gloves over what you already have on.

My role in the study is to collect samples of material from the bottom of the tank every three minutes and bring them to the station where someone else tests for conductivity of the samples. The study proceeds until three consecutive samples (from both the top and bottom of the tank) are the same conductivity. The whole process follows a strict procedure—similar to what you could find in a classroom lab, just on a much larger scale.

3 p.m. Tasks

After the mixing study, I return to my desk and continue whatever task I was working on from earlier that day.

4 p.m. Work day ends

I make a list of what I need to do for the following day and find a stopping point in the projects I'm working on.

- Read all of our Day in the Life blogs

- Learn more about internships at UNH

- Explore the College of Engineering and Physical Sciences

related posts:

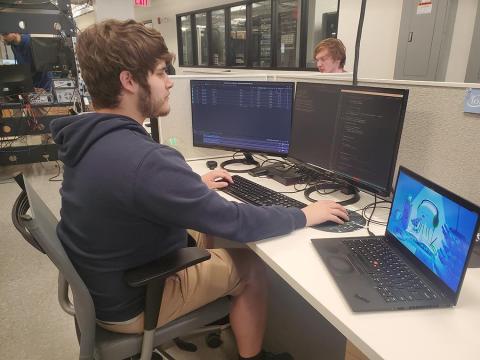

Justin's UNH Day in the Life

Let's explore the UNH InterOperability Laboratory (IOL) with Justin Choquette '24, a computer science major and student intern at the IOL. From bagels and iced coffee for breakfast, to writing code and attending team meetings at the IOL, to hanging out with friends after work, follow along on Justin’s day. read more about justin's day